|

|

|

Machining Center Accessories

|

|

AS

Series GROMAX Cartridge Spindle for CNC Machining Center

BS

Series GROMAX Cartridge Spindle for CNC Machining Center

HPAC-130S/130/160/200 GROMAX CNC Multi-Power Fixed Super

Lock Vise

|

| |

|

TOP

|

| GROMAX Cartridge

Spindle AS Series for CNC Machining Center |

|

| |

|

|

|

|

AS-C

Coolant Through Spindle Type

Click for larger view.

|

|

|

|

Features:

- Standard

spindle of mass production

- High

accuracy and high rigidy

- Same

spindle is available for various functions

- Changeable

spinning speed from 600rpm to 12000rpm

- External

part of spindle socket reserves the space for circular cooling

system to meet customer's requirement

- Every

set of spindle is attached by inspecting accuracy report

and temperature running graphy

|

|

| Specifications:

|

AS-CAT40A:

Standard Type

AS-CAT40B: Resersely Fastened Type

AS-CAT40C: Coolant through Spindle Type |

|

Model

|

Taper

|

Max.

Speed

(rpm)

|

Motor

(HP)

|

Pulley

|

Runout

Accuracy Test Bar/300mm (µm)

|

Max.

Temperature Rise (°C)

|

Price

|

|

AS-CAT40A-075-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40A-075-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40A-075-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40A-110-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40A-110-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40A-110-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-075-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-075-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-075-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-110-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-110-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40B-110-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-075-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-075-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-075-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-110-6

|

CAT40

|

6000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-110-8

|

CAT40

|

8000

|

10

|

8YUx40T

|

8

|

+15

|

|

|

AS-CAT40C-110-10

|

CAT40

|

10000

|

10

|

8YUx40T

|

8

|

+15

|

|

Note:

1. It can select BT, CAT or DIN specifications for spindle hole

and pull tool claw;

2. Customer can assign belt-pulley specifications;

3. Accept special specifications order. |

| |

|

TOP

|

| GROMAX Cartridge

Spindle BS Series for CNC Machining Center |

|

| |

|

|

Features:

- Standard

spindle of mass production

- High

accuracy and high rigidy

- Same

spindle is available for various functions

- Changeable

spinning speed from 600rpm to 12000rpm

- External

part of spindle socket reserves the space for circular cooling

system to meet customer's requirement

- Every

set of spindle is attached by inspecting accuracy report

and temperature running graphy

|

|

Model

|

Taper

|

Max.

Speed

(rpm)

|

Motor

(HP)

|

Pulley

|

Runout

Accuracy Test Bar/300mm (µm)

|

Max.

Temperature Rise (°C)

|

Price

|

|

BS-CAT50-150-5

|

CAT50

|

5000

|

20

|

8YUx60T

|

10

|

+20

|

|

|

BS-CAT50-185-5

|

CAT50

|

5000

|

25

|

8YUx60T

|

10

|

+20

|

|

|

BS-CAT50-150-6

|

CAT50

|

6000

|

20

|

8YUx60T

|

10

|

+20

|

|

|

BS-CAT50-185-6

|

CAT50

|

6000

|

25

|

8YUx60T

|

10

|

+20

|

|

Note:

1. It can select BT, CAT or DIN specifications for spindle hole

and pull tool claw;

2. Customer can assign belt-pulley specifications;

3. Accept special specifications order. |

| |

|

TOP

|

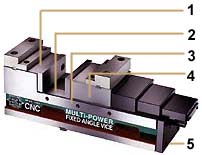

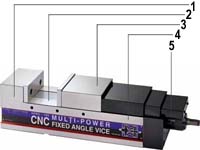

| GROMAX CNC Multi-Power

Fixed Super Lock Vise |

|

|

|

Features:

- The

patented Multi-Power System built of HIGH

GRADE BEARING STEEL

doubles the clamping force. Adjustable clamping force of

0~13200 Lbs.

- Slide

ways are HARDENED to HRC50°

to increase durability and maintain positioning height over

long use.

- Body

is made of Ductile iron above FCD60 grade for high precision

and durability. One solid body design enables high rigidity

with a force of 11000 Lbs. and the shape will deflect less

than 0.01mm (0.0004")

- SUPER

LOCK SYSTEM automatically pulls the workpiece down

to accurate position and most suitable for precision mold

making on machining centers.

- Can

be mounted horizontally or vertically.

|

| |

|

|

Fixed

Height makes several vises can be used together.

This product is especially for High Speed CNC Machining

Center. |

| |

|

|

|

| |

Standard Accessories:

- 2pcs

of alignment wedge

- 4pcs

of clamp

|

Optional Accessories:

- Cross-grooved

jaws

- V jaws

- Combination

jaws

- Step

jaws

|

|

|

Cross-Groved

Jaws

|

V

Jaws

|

Combination

Jaws

|

Step

Jaws

|

|

| Specifications:

(Material FCD60 Ductile Iron. Hardness HRC 50°) |

|

| |

|

|

Model

|

A

|

B

|

C

|

C1

|

D

|

E

|

F

|

G

|

Price

|

|

HPAC-130S

|

5.8"

|

3.7"±0.0004"

|

0~7.5"

|

6.1~13.4"

|

3.0"±0.0008"

|

0.7"

|

18.2"

|

19.7"

|

|

|

Model

|

Max.

clamping Force

|

H

|

I

|

J

|

K

|

L

|

M

|

Weight

|

|

HPAC-130S

|

13200 LBF

|

5.2"

|

0.7"

|

0.6"

|

7.0"

|

2.2"

|

7.1"

|

102.3 Lbs.

|

Extremely

high accuracy and repeatability.

Adjustable clamping force of 0~17600 Lbs.

|

|

Features:

- One-Piece

Construction provides high rigidity and super precision.

- Heat

Treated Slideways.

- Super

Lock System holds Jaw down on slideways and prevents

Jaw deformation.

- The

vise has 4 reference-surfaces for mounting horizontally

sideways or vertically.

- The

patented Multi-Power System built of HIGH

GRADE BEARING STEEL

provides extremely high clamping pressure. The pressure

is more consistent and eliminates all leakage and maintenance

problems associated with hydraulic vises.

|

| |

|

|

Fixed

Hight makes several vises can be used together.

This product is suitable for multi-unit applications on

both horizontal and vertical CNC Machining Centers as well as

Conventional Milling Machines where heavy duty machining requires

a very high clamping force. |

| |

|

|

|

|

Standard Accessories:

- 2pcs

of alignment wedge

- 4pcs

of clamp

|

| Specifications:

(Material FCD60 Ductile Iron. Hardness HRC 50°) |

|

| |

|

|

Dimentions

for 4-Jaw Pate Positions |

|

Model

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

I

|

J

|

K

|

L

|

Price

|

|

HAPC-130

|

2.8"

|

0.6"

|

0.7"

|

2.2"

|

4.5"

|

0.9"

|

5.8"

|

5.9"

|

5.9"

|

15.9"

|

2.6"

|

5.2"

|

Call

|

|

HAPC-160

|

3.3"

|

0.6"

|

0.7"

|

2.3"

|

5.1"

|

0.9"

|

6.3"

|

6.4"

|

6.5"

|

19.5"

|

2.6"

|

6.3"

|

Call

|

|

HAPC-200

|

3.5"

|

0.6"

|

0.7"

|

2.5"

|

5.9"

|

0.9"

|

6.7"

|

6.8"

|

7.5"

|

22.4"

|

2.6"

|

8.3"

|

Call

|

|

Model

|

Max.

clamping Force

|

M

|

N

|

O

|

P

|

Q

|

Q1

|

Q2

|

Q3

|

Weight

(Lbs)

|

|

HAPC-130

|

13200 LBF

|

0.8"

|

2.5"

|

4.1"

|

3.9"±0.0004"

|

0~7.1"

|

7.1"~9.4"

|

7.1"~11.4"

|

7.1"~15.0"

|

103.4

|

|

HAPC-160

|

14300 LBF

|

0.8"

|

2.5"

|

4.6"

|

4.0"±0.0004"

|

0~9.4"

|

9.4"~12.6"

|

9.4"~14.2"

|

9.4"~18.5"

|

143

|

|

HAPC-200

|

17600 LBF

|

0.8"

|

2.5"

|

4.8"

|

4.3"±0.0004"

|

0~11.0"

|

11.0"~14.2"

|

11.0"~16.5"

|

11.0"~21.3"

|

209

|

TOP

|

|