|

|

|

New Machines

|

|

SDNC16P/40P/60P

GROMAX CNC Drill EDM (with auto tool changer optional)

UH-1250/1000 GROMAX Bed-Type Universal Milling Machine

H-1250/1000

GROMAX Bed-Type Horizontal Milling Machine

HV-1250A/1000A GROMAX Bed-Type

Vertical Milling Machine

G Series GROMAX Horizontal Turning Center

V3EC

GROMAX MAXIMILL Machining Center

HS

Series GROMAX High Speed Precision Machining Center

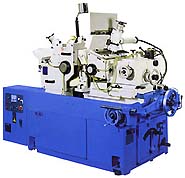

RC

Series GROMAX Centerless Grinder

H

Series GROMAX Pivot Type/Column Type/Miter Cutting

Bandsaw

HM

Series GROMAX Hydraulic Tapping Machine

AE/AS/AT Series GROMAX Air Tapping

Machine

K3VLC GROMAX Knee-Type CNC Mill with Centroid Control

|

|

| |

|

TOP

|

| GROMAX CNC Drill

EDM (w/ auto tool changer optional) |

|

| |

| |

|

TOP

|

| GROMAX Bed-Type

Universal Milling Machine |

|

| |

|

UH-1250A/U-1250B

Click for more details.

|

UH-1000A/U-1000B

Click for more details.

|

|

|

|

- UH:

1. With universal head can do vertical, horizontal,

and any angle milling

2.

Without universal head: only horizontal milling by the

spindle of column

- U:

With universal head can do vertical, horizontal, and any

angle milling

- A:

Distance of spindle center to column surface is 20"

- B:

Distance of spindle center to column surface is 16.8"

|

| |

|

TOP

|

| GROMAX Bed-Type

Horizontal Milling Machine |

|

| |

|

H-1250/H-1000

Click for more details.

|

Standard Accessories:

- Coolant pump

(1pc)

- Tool Box (1pc)

- Heavy-duty

eye bolt (2pcs)

- Standard screw

washer (4pcs)

- L-shaped spanner

(1set)

- Socket spanner

1" (1pc)

Socket spanner 1.2" (1pc)

|

- Grease gun

(1pc)

- Shifting

spanner 1.8" (1pc)

- Spindle

drawing bar (1pc)

- Adjusting

pin 0.32" (1pc)

Adjusting pin 0.24" (2pcs)

- Automatic

lubricating system (1set)

- Cross

screw driver (+) (1pc)

- Cross

screw driver (-) (1pc)

- Head

rotary round stick (1pc)

|

| |

|

TOP

|

| GROMAX Bed-Type

Vertical Milling Machine |

|

| |

|

HV-1250A/HV-1000A

Click for more details.

Click for more details.

|

Standard Accessories:

- Coolant pump

(1pc)

- Tool Box (1pc)

- Heavy-duty

eye bolt (2pcs)

- Standard screw

washer (4pcs)

- L-shaped spanner

(1set)

- Socket spanner

1" (1pc)

Socket spanner 1.2" (1pc)

|

- Grease gun

(1pc)

- Shifting

spanner 1.8" (1pc)

- Spindle

drawing bar (1pc)

- Adjusting

pin 0.32" (1pc)

Adjusting pin 0.24" (2pcs)

- Automatic

lubricating system (1set)

- Cross

screw driver (+) (1pc)

- Cross

screw driver (-) (1pc)

- Head

rotary round stick (1pc)

|

| |

|

TOP

|

| GROMAX Horizontal

Turning Center |

|

| |

|

|

|

Features:

All

GROMAX G Series Turning Centers are based on the latest Japanese

technology and components and manufactured under strict ISO

9001 & ISO 14001 regulations. Knowing that the complexity

of present and future machining processes require more than

just high quality machines, we offer you the GROMAX ADVANTAGE:

- Obtain

fast cycle times with extra power and faster speeds in every

machine.

- Save

manpower and increase accuracy by eliminating manual part

handling with our full range of multi-process machines and

fully automated loading systems.

- All

machines are loaded with standard features and accessories

that are not available or costly options on other brands.

[click

for more details]

|

| |

|

TOP

|

| GROMAX MAXIMILL

Machining Center |

|

| |

|

|

|

| Comparison: |

MAXMILL

|

Competitor

|

| X,Y,Z

Travels |

26"x16"x16"

|

16"x12"x10"

|

| Weight |

4200

lbs.

|

3400

lbs.

|

| Table

Load |

660

lbs.

|

500

lbs.

|

| Hardened

/ Ground Ways |

Yes

|

No

|

| High

Speed Machining |

Included

|

$5,995

|

| Solid

State HD |

Included

|

No

|

| 3.5"

Floppy Drive |

Included

|

$495

|

| Conversational |

Included

|

$495

|

| Probing

with Probe |

$1,295

|

$7,995

|

| Auto

Tool Setter |

$495

|

$3,150

|

| Digitizing

|

$3,000

|

$20K

+ 3rd Party Add On

|

| LAN/Net

Ready |

Included

|

$2,995

|

| Warranty

|

1

Year

|

6

Months

|

| |

|

|

| [click

for more details] |

|

| |

|

TOP

|

| GROMAX High Speed

Precision Machining Center |

|

Excellent for high

speed machining and engraving!

|

|

HS Features—First

Class HSC Technology

- The

HS Machine is purpose-built for outstanding HSC performance

which is required in today's modern mold making environment.

The machine is designed to achieve very high "G"

values and low harmonic vibrations ensuring ultra fast corner

transitions, extremely high accuracy and super fine surface

finishes.

- All

components used are of the highest quality and designed

for a long service life.

- The

highly rigid machine structure allows the high-dynamic AC

drive system to be tuned to a high state ensuring that maximum

performance is achieved.

[click

for more details]

|

|

Effectively

avoids dust particles splashing out especially when machining

materials as graphit, artificial wood, carbon fiber, etc.

|

| |

|

TOP

|

| GROMAX Centerless

Grinder |

|

Economical Series!

RC Series are general purpose centerless grinding machines intended

for rapid, accurate grinding of small diameter work. High quality

at low cost is one of the outstanding features. They are high-productive,

versatile, durable machines with maximum ease of operation and safety

design.

[click

for more details]

| |

|

TOP

|

| GROMAX Pivot/Column/Miter

Cutting Bandsaw |

|

| |

| |

|

TOP

|

| GROMAX Hydraulic

Tapping Machine |

|

| |

|

HM Series

Click for more details.

|

Features:

- Rapid

positioning and high machinery speed increase productivity

- Lower

tap damage pate, higher thread accuracy

- Tap

shall never break for tapping through-hole or blind-hole

- Tapping

for heavier work piece requires large work area

- Lower

machining cost than by CNC machine, drilling tapping machine

or manual tapping operation

- Easy

operation, no experience required

[click

for more details]

|

| |

|

TOP

|

| GROMAX Air Tapping

Machine |

|

| |

| |

|

TOP

|

| GROMAX Knee-Type

CNC Mill with Centroid Control |

|

ISO

9002 Quality Assurance:

0.0004" positioning accuracy

0.0002" positioning repeatability

|

|

Features:

- ISO 9002 quality assurance

- 3HP variable speed head

- 3-Axis digital DC servo drive

motor 17 in/lb. or 29in/lb. optional (M-15 Controller) and

40 in/lb. (M-400 Controller)

- One-piece construction head

for CNC use

- Safety handwheel

- Class 7 bearing for spindle

run out less than 0.0002"

- Hardened and ground table

with center T-slot. Ground for quick setting

- Meehanite casting for rigid

construction

- Built-in coolant pump

- 1-1/4" precision ground

ball screws with double nut for accuracy movement

- Hardened and ground box way

with trucite B coating

[click

for more details]

|

TOP

|

|

Click for more details.

Click for more details.